ME Piston Crown Failure –

Piston Cooling Oil Temperature Analysis

Background

While sailing, the ship’s crew received a piston cooling oil (PCO) high temperature alarm (65°C) that led to a main engine slow down and eventual stoppage of the engine for investigation.

Condition found

Upon investigation, the crew found a crack in the piston crown with cooling oil leaking out. The crew isolated the unit and carried out a unit overhaul at the next opportunity. Figure 1 displays the PCO outlet temperatures prior to, during, and after the engine slowdown and shut down due to high PCO outlet temperatures.

How smartship™ can prevent/mitigate this type of failure

SMARTShip has two applications that can be configured to better monitor and alert on anomalous operating conditions to inform staff about them.

1

SMARTNotification – user customizable notification manager allowing users to create alerts. A notification was created for when an individual unit PCO temperature deviation from average exceeds 1.5°C.

2

Asset AI – An advanced anomaly detection application using AI/ML. The application was configured to monitor and alert on anomalous individual unit PCO temperature deviation from average and individual unit PCO high temperature with respect to load and PCO inlet temperature.

Alpha ori technologies’ approach

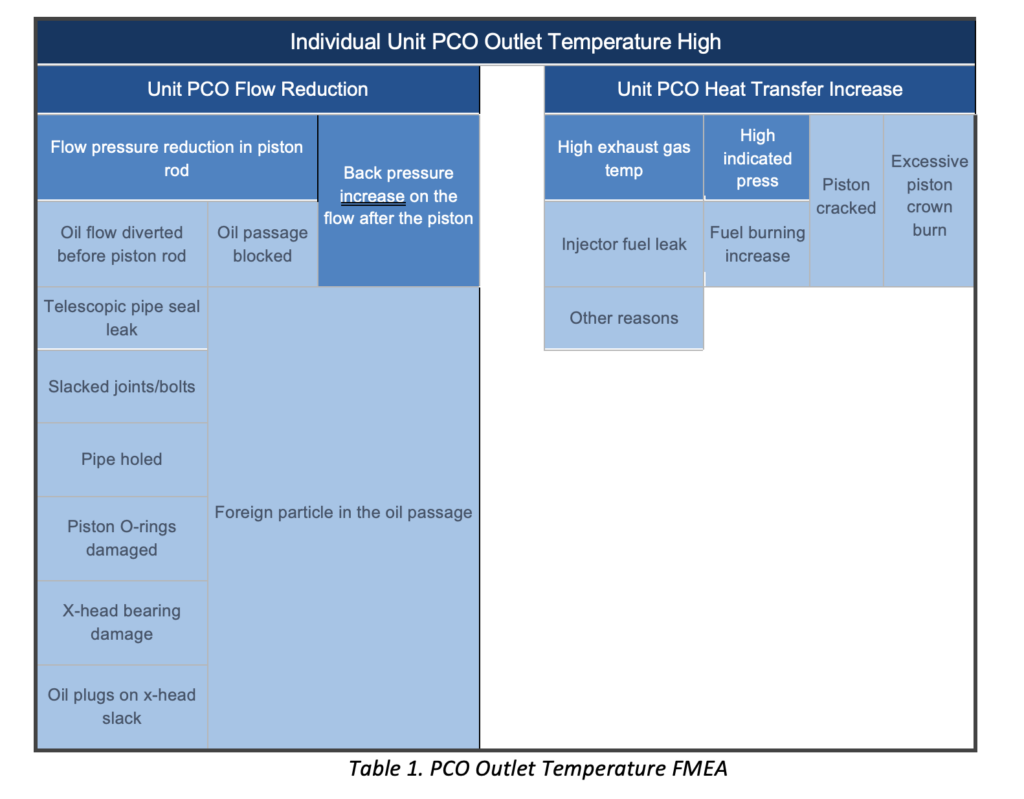

A holistic approach is taken when evaluating how to properly monitor equipment and associated parameters. Failure Mode & Effects Analysis (FMEA) is performed on the equipment to ensure the approach taken is based on engineering fundamentals and historical and incident data is analyzed to support the engineering approach and assumptions.

Failure Mode & Effects Analysis (FMEA) enables finding the respective failure mode, associated failure indication and root causes.

SMARTNotification – Unit PCO Temperature Deviation from Average

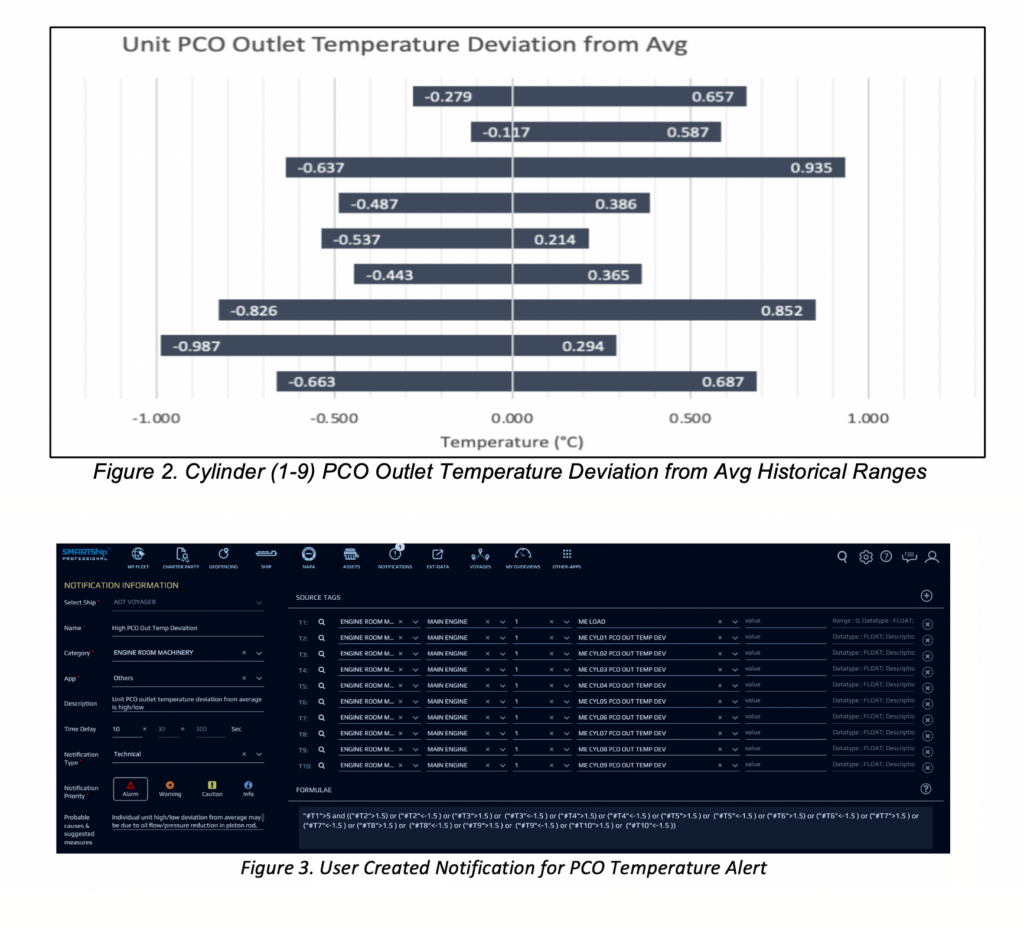

A notification was set to alert users if any unit PCO outlet temperature deviation exceeds +/-1.5°C with a persistence of 5 minutes. The threshold was based on historical data analysis. Figure 2 displays the historical normal variation of PCO outlet temperature deviation over a 1-year period for each unit. The diagram indicates that the individual cylinder PCO temperature deviation has been well maintained (all within +/-1°C).

Figure 3 shows the user interface used to create the notification within SMARTShip. The notification manager allows users to create custom notification formulas with associated information.

Asset ai (machine learning)

Two AI based modeling approaches were evaluated:

- Single variable model based on individual unit historical PCO temperature deviation from average.

- Multivariable model of PCO outlet temperature based on engine load and PCO Inlet temperature.

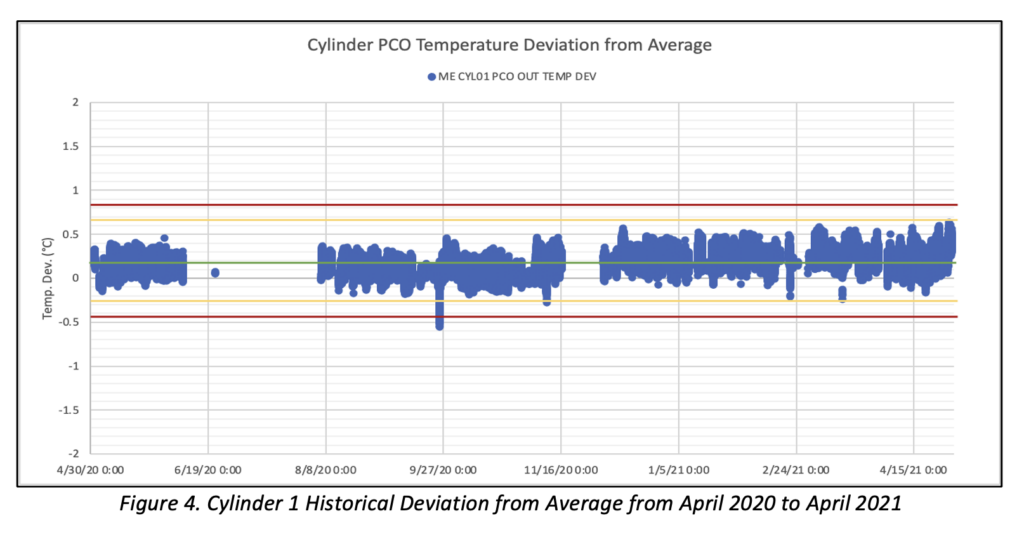

Figure 4 displays one year of historical unit 1 PCO outlet temperature deviation from average data while the main engine was in operation – this data was used to generate the single variable model. Statistical methods were used to find the mean and normal variation of the data to set a baseline and associated warning/alarm limits for the individual unit.

For the multivariable model approach, instead of monitoring the deviation from average, the unit PCO outlet temperature is monitored. Through engineering and data analysis it was determined that the primary contributors to PCO outlet temperature are the PCO inlet temperature and the engine load.

A ML model was generated with PCO inlet temperature and load to identify what the expected outlet temperature should be at various engine loads and inlet temperatures. Figure 5 displays the Asset AI model detecting and alerting on a similar piston crown failure from a different vessel.

The figure demonstrates the dynamic alerting capability based on the fluctuating engine load and PCO inlet temperature. In the top chart, the green line represents the machine learned baseline, the yellow and red line represent the anomalous warning and alarm limits, and the blue is the actual PCO outlet temperature data.

Conclusion

After the AI models were generated, they were superimposed on the actual failure data, to see how the models performed.

- The single variable Asset AI model monitoring the individual unit deviation from average is the most sensitive and would have alerted 24 hours prior to the trip. The only limitation to this model is that if the temperature of multiple units increases simultaneously, the deviation for all units may still be within a normal range. Figure 6 displays the failure data with the AI model limits and it can be seen the model detected the anomalous behavior after the initial approx. 1°C increase 24 hours prior to the AMS alarm.

- The multivariable model generated was slightly less sensitive and would not have alerted on the first temperature increase highlighted in Figure 6, but rather would have alerted at the second major increase 4h prior to the AMS alarm. This model, however, has no dependency on the average and therefore is better at detecting if multiple units are anomalous simultaneously. For this reason, both models were deployed for complete coverage

Static limit AMS alarms onboard vessels often offer little to no time to mitigate or correct potential equipment issues and can result in various undesired outcomes for owners, operators, and vessel staff. As digitization is becoming the norm in shipping and advancements and incorporation of AI are commonplace the methodologies to monitor equipment in the marine industry are ripe for change and Alpha Ori’s SMARTShip Platform is leading the way.AI based predictive maintenance solutions provide real possibilities to embark on condition-based maintenance strategies to increase reliability and reduce equipment downtime.

About the author

Tom Callahan is a Product Manager at Alpha Ori Technologies. He has a decade of experience in the marine industry and predictive maintenance applications. Contact: thomas@alphaori.sg